The coating on tablets helps withstand the gastric environment and also has many advantages like masking the odor, color, and taste of a drug along with physical and chemical protection. Sometimes tablet’s quality may be improper if, the proper method and technique are not followed during the coating process. So to avoid these problems, we can apply a few techniques to solve these types of issues. In this article, we will discuss all these types of tablet coating problems and remedies with the help of an expert.

List of Tablet Coating Problems:

Below is the List of problems that we faced during the coating process.

- Blistering

- Cratering

- Cracking

- Picking/Sticking

- Pitting

- Blooming

- Blushing

- Roughness

- Colour Variation

- Bridging of Logo

Related Topics: Capsule Defects and Remedies

Common Tablet Coating Problems with Remedies:

Below is a detailed explanation of Each coating defect in Pharmaceutical tablets along with their Reason, Cause, and how to fix it.

1. Blistering:

The blistering is the local detachment of film from the surface of tablets.

| Reason | Cause | Remedies |

| This is because of the gas Penetration inside/ underneath the film. It may be due to overheating either during spraying or at the end of the coating process. | This is because of the heating and temperature that Affect the plasticity, strength, and adhesion of the film. | Use mild heating or temperature conditions during the Coating process. |

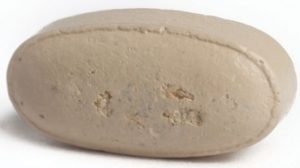

2. Cratering:

In this defect, volcanic-like craters may appear on the tablet surface.

| Reason | Cause | Remedies |

| During the coating process, the coating solution penetrates the tablet’s surface, often at the Crown area where the surfaces are more porous, causing localized disintegration of the core and disruption of the coating. | Inefficient drying. | ✅ Decrease spray Rate ✅ Use efficient and optimum drying conditions. |

| The highest weight of spraying solution or application of coating solution. | Increase viscosity of coating solution to decrease spray application rate. |

3. Cracking (Splitting):

When the coating layer of the tablet fractures or separates around the edges, this is referred to as cracking.

| Reason | Cause | Remedies |

| When the internal tension of the film is beyond its tensile strength, cracking occurs. | This is common if the coating materials have Higher molecular weight polymers or polymeric mixtures. | ✅ Try to add lower molecular weight polymers or a polymeric mixture ✅ Adust with plasticizer concentration and its types. |

4. Picking/Sticking:

This defect is due to the coating film pulling away from the Tablets’ surface when tablets stick together during the coating process.

| Reason | Cause | Remedies |

| This condition is similar to cratering and also produces picking due to wet tablets moving inside bad stick together and then breaking apart. | Inefficient drying | Use optimized drying conditions to increase the inlet air temperature. |

| Over-wetting due to high spray rate. | ✅ Decrease spray rate of the coating solution ✅ Increase viscosity of the Coating solution. | |

| Low pan speed rate. | Increase pan speed. |

5. Pitting:

Pitting is the defect that occurs on the tablet’s surface without any visible disruption of the film coating.

| Reason | Cause | Remedies |

| Pitting is because of the higher temperature of the tablet Core compared to the melting point of the material used in the tablet formulation process. | Inefficient drying | Use optimized drying conditions to increase the inlet air temperature. |

| Inappropriate drying air inlet temperature. | ✅ It may be due to Dispensed material with preheating procedure at the start of coating and the change in the drying (inlet air) temperature. The temperature of the tablet is not greater than the melting point of the material used in the coating process. ✅ Control drying temperature. |

Related post: Tablet manufacturing defects and remedies

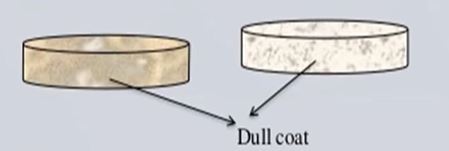

6. Blooming:

This effect is due to a change in the tablet’s coating color (dull color) after the prolonged storage of tablets at a higher temperature.

| Reason | Cause | Remedies |

| It is due to the collection on the surface of the low molecular weight ingredients (plasticizer) included in the coating formulation. | Blooming may be due to the high concentration and low molecular weight of the plasticizer. | Decrease the concentration of the plasticizer and the increased molecular weight of the plasticizer. |

7. Blushing:

Blushing is the whitelist specks or film haziness.

| Reason | Cause | Remedies |

| Blushing may be Due to the precipitated polymer provoked by the use of high coating temperature at about the thermal gelation temperature of the polymers. | High coating temperature | This problem can be avoided by a decrease in the drying air temperature. |

| The sorbitol in the formulation causes the most significant fall in the thermal gelation temperature of some cellulose like hydroxypropyl cellulose (HPC), hydroxypropyl methylcellulose(HPMC) methylcellulose, and cellulose ethers. | by avoiding using sorbitol with hydroxypropyl cellulose, hydroxypropyl methylcellulose, methylcellulose, and cellulose ether. |

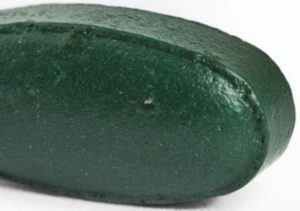

8. Roughness (“Orange peel”)

The rough surface of the tablet gives it the look of an “Orange Peel,” and it may also have a dull instead of a shiny finish.

| Reason | Cause | Remedies |

| “Orange peel” might be the cause of a soft tablet due to inadequate tablet coating. | “Orange peel” might be the cause of a soft tablet due to inadequate tablet coating. It can also be produced by a high spray pressure along with a quick spray rate, resulting in uneven tablet coating. | ✅ Use moderate drying conditions or add extra solvents to lower the viscosity of the coating solution, which leads to improved atomization. ✅ Minimize the spray rate. |

9. Colour Variation:

This defect involves variation in the color of the film.

| Reason | Cause | Remedies |

| Change in the frequency and duration of the Tablet appearance in the spray zone or the size/ shape of the spray zone. | ✅ Irregular the Spray pattern ✅ Lack of proper coating ✅ Improper mixing of materials | ✅ Do geometric mixing ✅ Use different plasticizers and additives |

| Color variation may be due to the Migration of the soluble dyes-plasticizer and other additives during the drying process. | Use a mild drying condition. |

10. Bridging of Logos (Engrave area)

Logo bridging is due to the high concentration in-filling of the coating solution inside engraved/logo areas.

| Reason | Cause | Remedies |

| Coated tablet logo bridging happens when an internal stress component develops sufficiently enough to cause partial or total separation of the coating from the tablet surface inside the logo/Engrave area. | ✅As a result, liquid droplets get concentrated in the engraved area. This results in a greater polymer concentration within the logos/ engrave areas. | ✅ Add IPA enough to the coating solution to improve dispersion ✅ Use fine atomization |

images credit- all image credits to sensientpharma.com and screenshots taken by the author.

Read Our Guide on Sugar coating Process

Final Conclusion:

Above tablet coating defects are the most common issues in pharmaceutical industries, and it is not a big issue, these types of common tablet coating issues can easily be tackled by using a given solution inside this article.

If you have any questions regarding coating defects in tablets, ask us by commenting below. you are most welcome if you have any suggestions regarding tablet defects and solutions.

Related Topic: Blister Defects and Remedies in Pharmaceutical

Naresh Bhakar is the Founder and Author at Pharmaguddu.com, bringing his extensive expertise in the field of pharmaceuticals to readers worldwide. He has experience in Pharma manufacturing and has worked with top Pharmaceuticals. He has rich knowledge and provides valuable insights and data through his articles and content on Pharmaguddu.com. For further inquiries or collaborations, please don’t hesitate to reach out via email at [email protected].