SOP for Dry Heat Sterilization in injection section

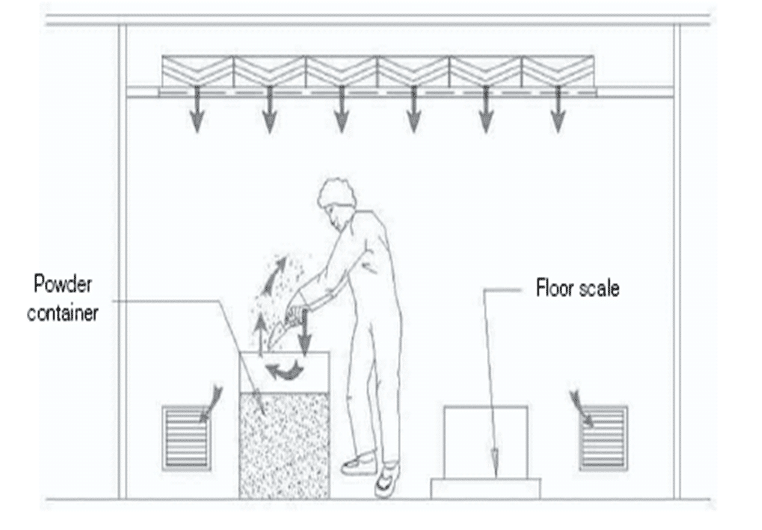

Read about the Standard Operating procedure on DHS along with precautions, and DHS setting for Aspectic and Non-Aseptic areas. 1.0 Objective: To lay down a procedure for operation Dry Heat Sterilization (DHS) in the injection section. 2.0 Scope: This SOP on Dry Heat Sterilization is applicable to the Injection Section of the production department at the plant. 3.0 Responsibilities:Officer- Production for implementation … Read more